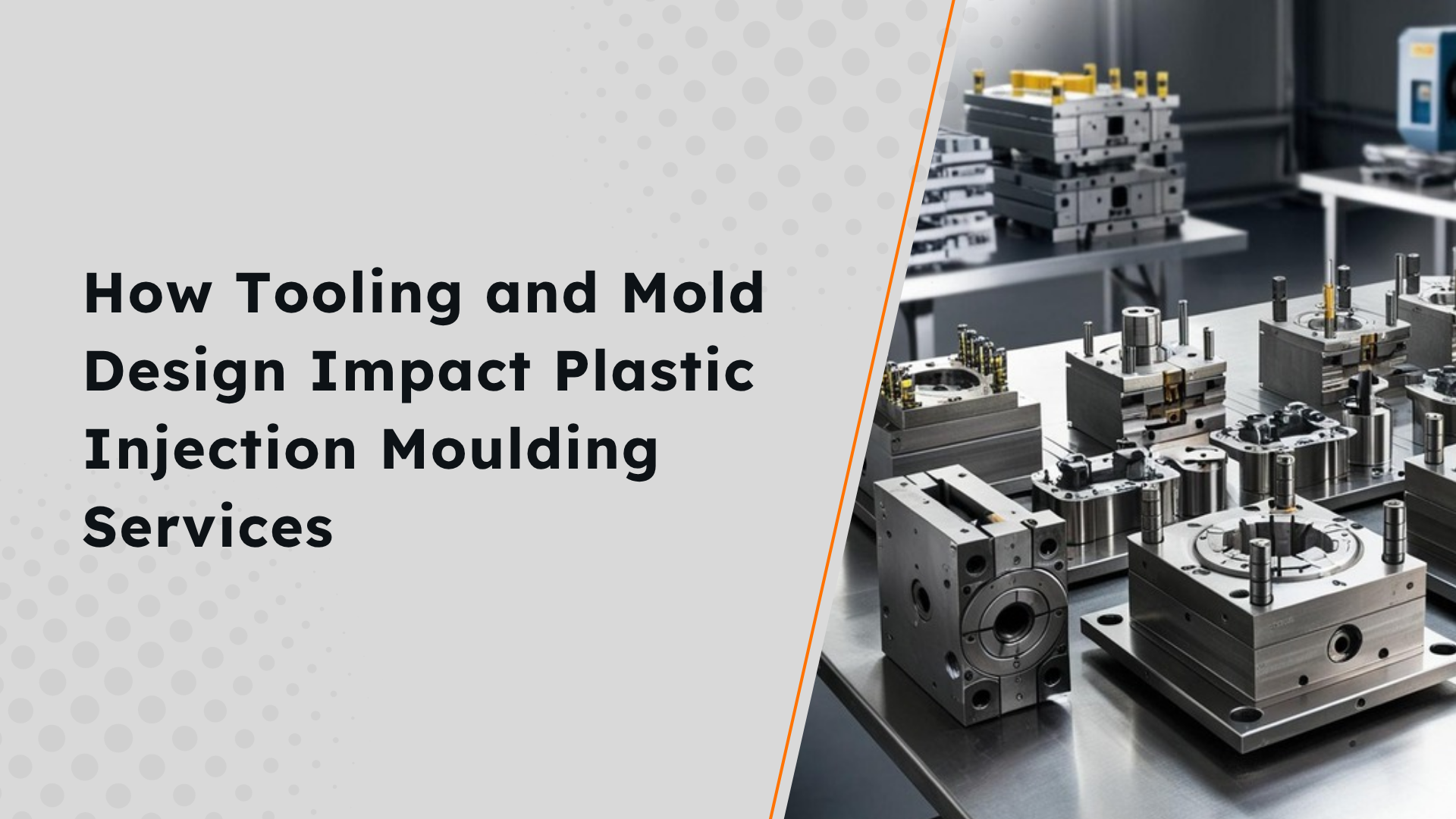

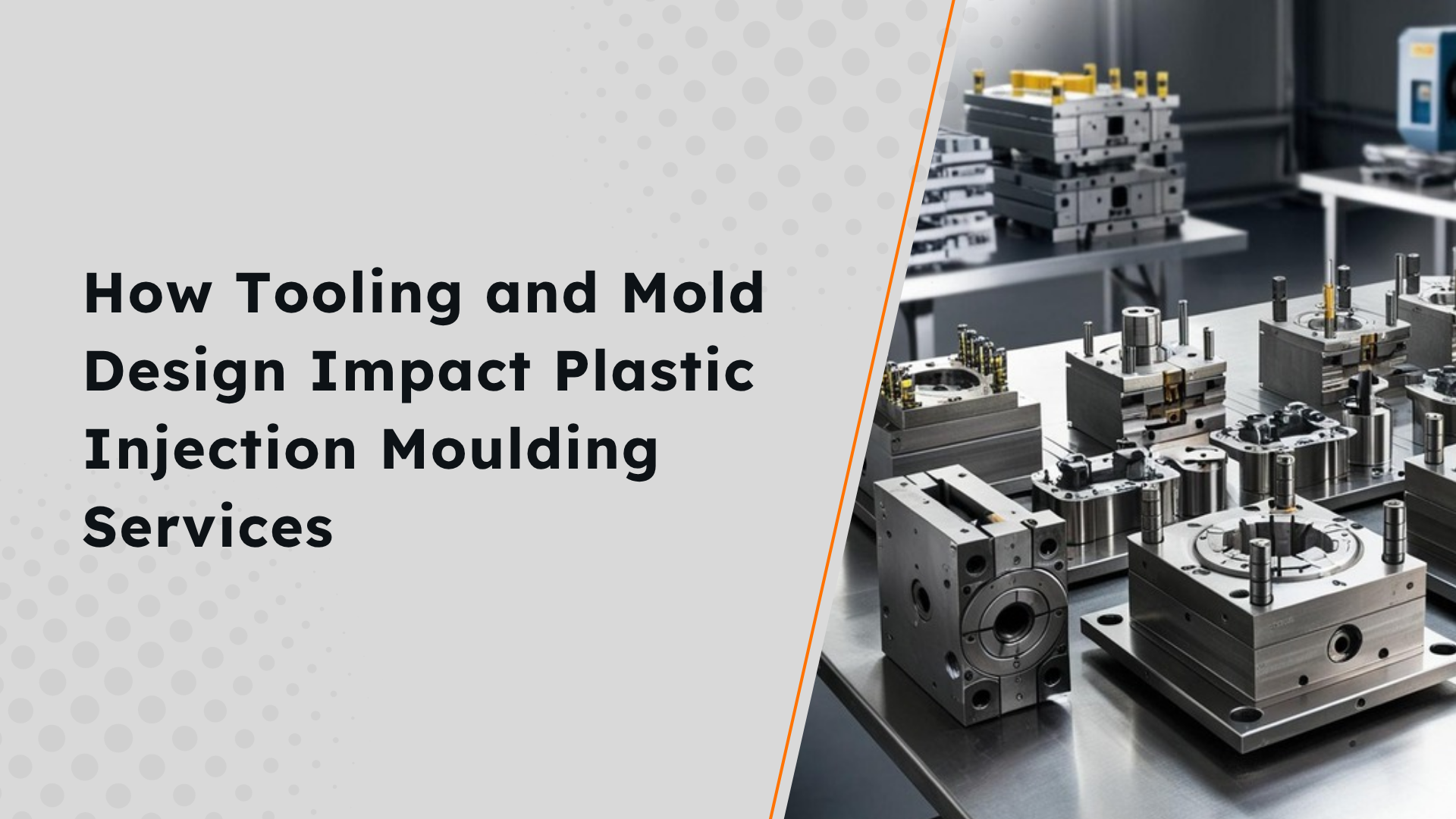

From a Plastic Injection Moulding Services perspective, tooling and mould design can be viewed as the prerequisite for successful manufacturing. Final plastic components gain quality, precision, and durability, and they proceed from good tooling and mould design.

A product designer or a manufacturer looking for custom injection moulding services cannot afford not to understand how tooling and mould design work to provide efficiency, consistency, and economy.

What Is Tooling in Plastic Injection Moulding?

Tooling refers to all the processes involved in mould making in the plastic injection moulding process. These moulds will basically control the shape, size, texture on the surface, and tolerances of the final product in plastic. If a tool is well designed, it will allow for faster cycle times, fewer defects, and a longer mould life- the most important factors in rendering an efficient Plastic Injection Moulding Services.

How Does Mould Design Affect Injection Moulding?

Mould design is imperative for even material flow, proper cooling, and minimal warping or shrinkage issues. Improper design may bring up common defects such as flash, sink marks, and short shots. For custom injection moulding services, the mould is designed to tailor to your needs for the geometry and function of your part, which guarantees the best results and less post-processing.

Why Tooling Quality Matters in Custom Injection Moulding Services

High-quality tooling:

Reduces material waste

Speeds up production

Enhances product precision

Cuts down long-term maintenance costs

For businesses partnering with a plastic mould company, ensuring that tooling meets exact product specs can drastically improve production efficiency and product quality.

Finding the Right Plastic Mould Company

When you are deciding on a company to partner with for your plastic injection moulding needs, be sure to select a plastic mould company that also has in-house tooling and design experience. This provides better quality control, faster lead times, and design support for your specific project.

FAQs

How does tooling affect the price of plastic injection moulding?

Tooling is a large investment at the outset. Still, high-quality tooling will result in lower-cost, higher-quality products in the long term as cycle times will decrease and the performance of the end product will be consistent.

Can I make mould changes after production has started?

It is possible to make small mould changes, but big mould changes can be difficult and expensive. This is why it is so important that you start off with a good plastic mould company.

Conclusion

Tooling and mould design are the backbone of efficient and accurate Plastic Injection Moulding Services. By investing in quality design and working with an experienced plastic mould company, manufacturers can unlock better quality, speed, and cost savings, especially when leveraging custom injection moulding services designed for their unique requirements.

Related Blogs

From a Plastic Injection Moulding Services perspective, tooling and mould...

Read More

Plastic ultrasonic welding is one of the modern methods of...

Read More

In the current rapid manufacturing environment, speed and accuracy are...

Read More

In the current high-speed manufacturing world, companies can't afford to...

Read More